Record Restore

Bring your records back to life free from snaps, crackles and pops.

Pick up a Record Restore Box Set or use our vinyl record cleaning service.

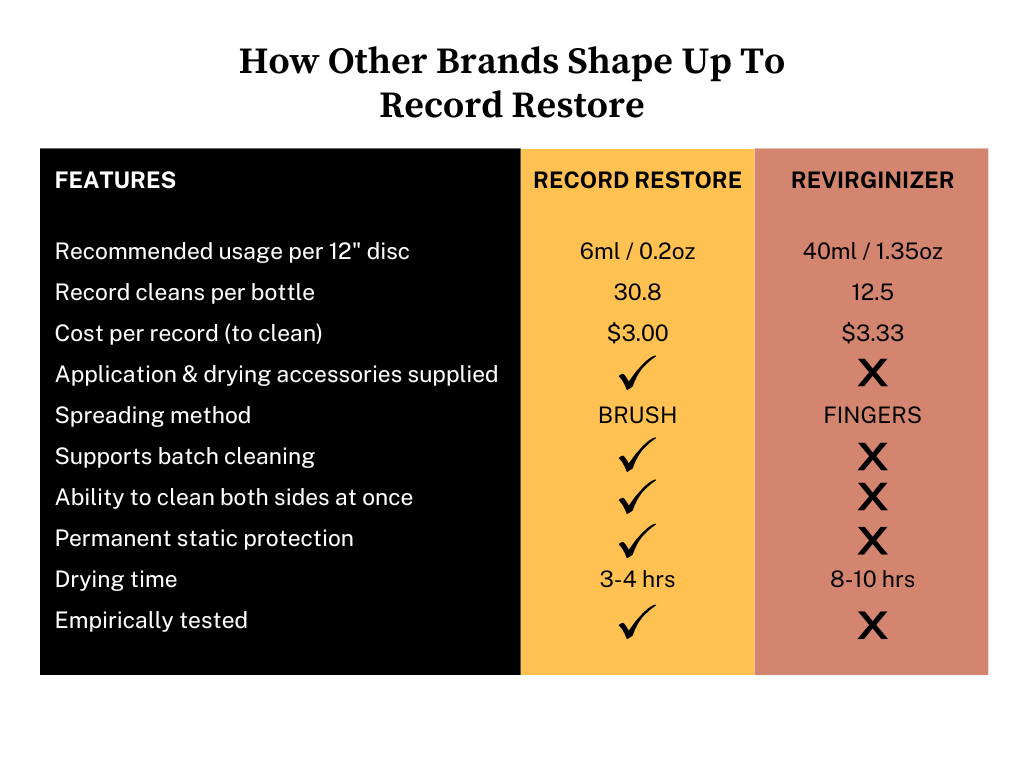

Drying time aside, cleaning with Record Restore takes no more time than other methods.

Older collections enjoy an 11db increase in overall signal to noise ratio and an 8db improvement to the peak noise floor

Accessories

A range of helpful utilities as well as spare parts and accessories.

SCA Stylus Tip Cleaner

Safely clean dust and grit from your stylus with the SCA Stylus Tip Cleaner (STC). The STC's uniq...

SCA Record Dust Brush

The SCA Record Dust Brush is not a record cleaner. Indeed, it might be asked why, if having clean...

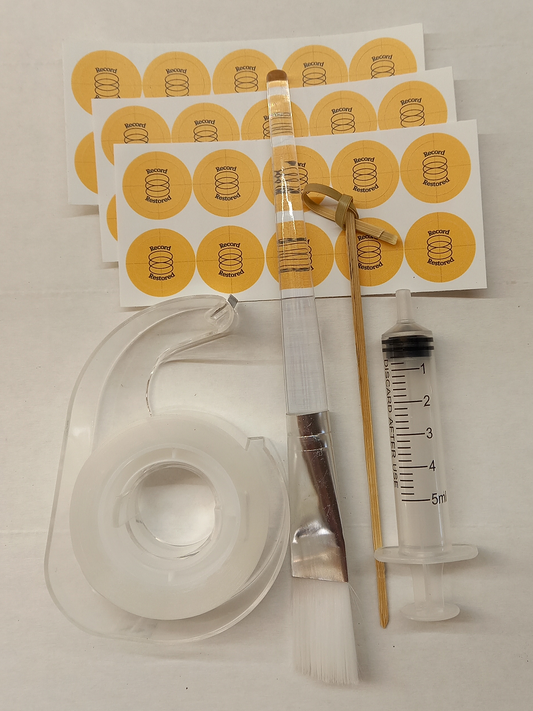

Record Restore Box Set Accessories Pack

This accessories pack is a replacement for components in the Record Restore Box Set. The Box Set ...

SCA Stylus Tip Cleaner - Tak pad replacement

SCA STC-Tak pad replacement STC Tak pad replacement (4 gms)

SCA Vinyl Coasters

The stylish table top protector. Six in a pack - add a pack to your next Record Restore order.